Front Anti-Roll Bar (FARB) Development

Fast-adjustable blade-style anti-roll bar designed with multibody simulation and manufactured using 3D-printed soft jaws and waterjet fixturing. Enabled sub-30 second stiffness changes compared to 10–15 minutes with previous designs.

Our Formula UBC car needed a front anti-roll bar that was easy to tune, lightweight, and predictable. I designed a blade-style, rapidly adjustable FARB so we could change roll stiffness in under 30 seconds instead of the 10–15 minutes it took with previous designs.

Goals

- Fast adjustability so we could tune roll stiffness between sessions (or even between runs)

- Predictable, linear stiffness range matched to our overall roll-stiffness distribution targets

- Manufacturable on student-team equipment, while taking advantage of my co-op shop access at Zaber

Design & Analysis

- Modeled the FARB (torsion bar, blades, and links) and suspension in a Simulink multibody model

- Used the model as a design calculator to:

- Sweep bar diameters, blade geometries, and motion ratios

- Target a stiffness range that worked with the rear bar and spring package

- Maximize the linear region of operation

- Linked the simulation results back to CAD so geometry changes could be quickly re-evaluated

- Indexed blade positions so each setting corresponded to a known, repeatable stiffness

Simulink multibody model used for stiffness calculations and geometry optimization

Manufacturing

A lot of the machining was only practical because of my access to the machine shop at Zaber during co-op, plus aggressive use of 3D-printed tooling:

Bar ends & blades

- Turned the bar ends from 4130 steel, then:

- Used 3D-printed soft jaws to hold them accurately in the mill for mitering and secondary ops

- Machined the blades with a combination of:

- Conventional fixturing and

- 3D-printed soft jaws to mill the flat and tap the adjustment hole without distorting the part

Left: Blade workholding with 3D-printed soft jaws. Right: Final milling operation

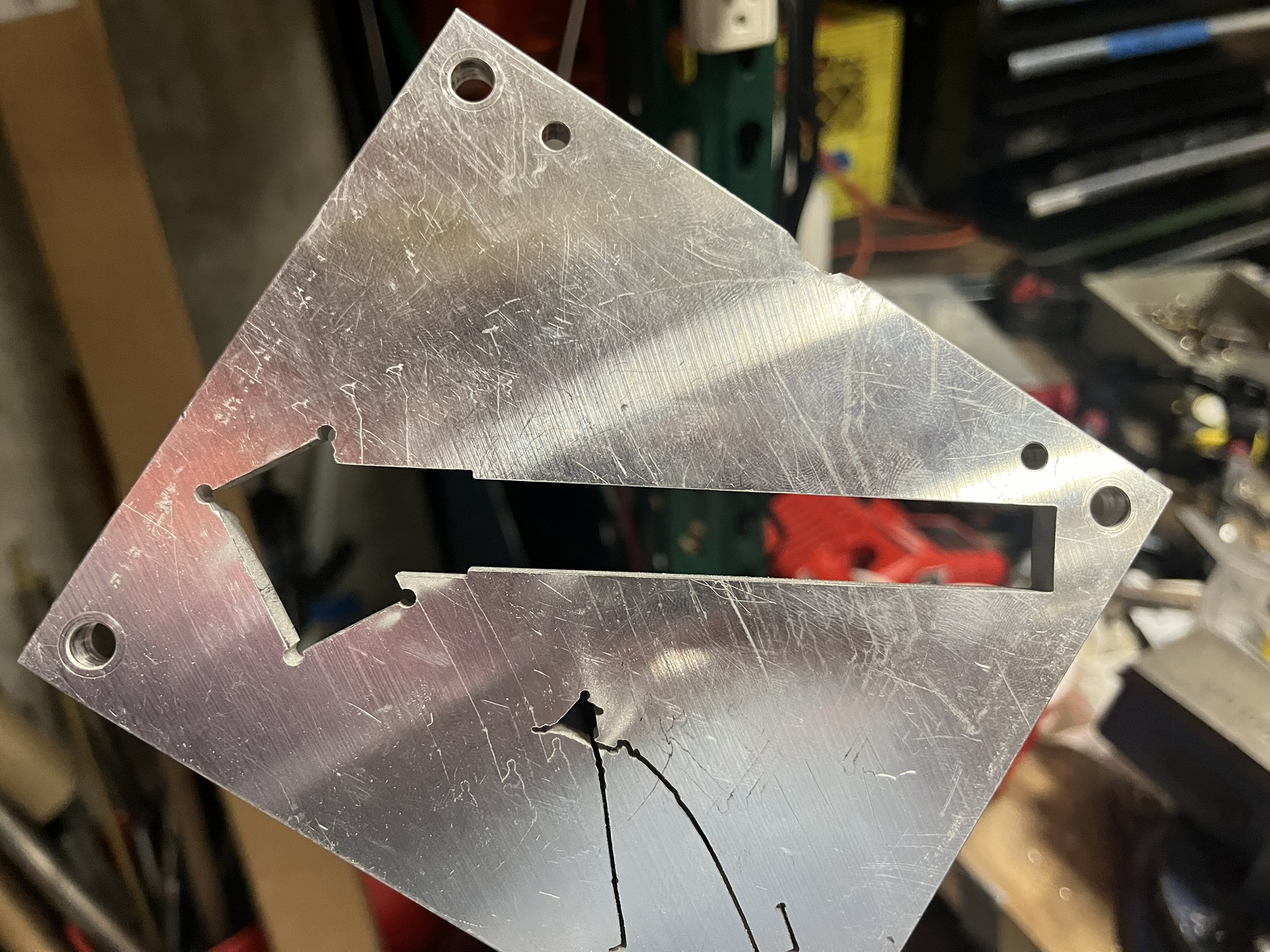

Torsion bar & welding setup

- Turned down the torsion bar to the required diameter/profile

- Waterjet-cut a plate to match the bar-end profile and used it as a welding jig:

- Held the bar ends at the correct angle and spacing

- Kept everything aligned during welding to minimize runout and rework

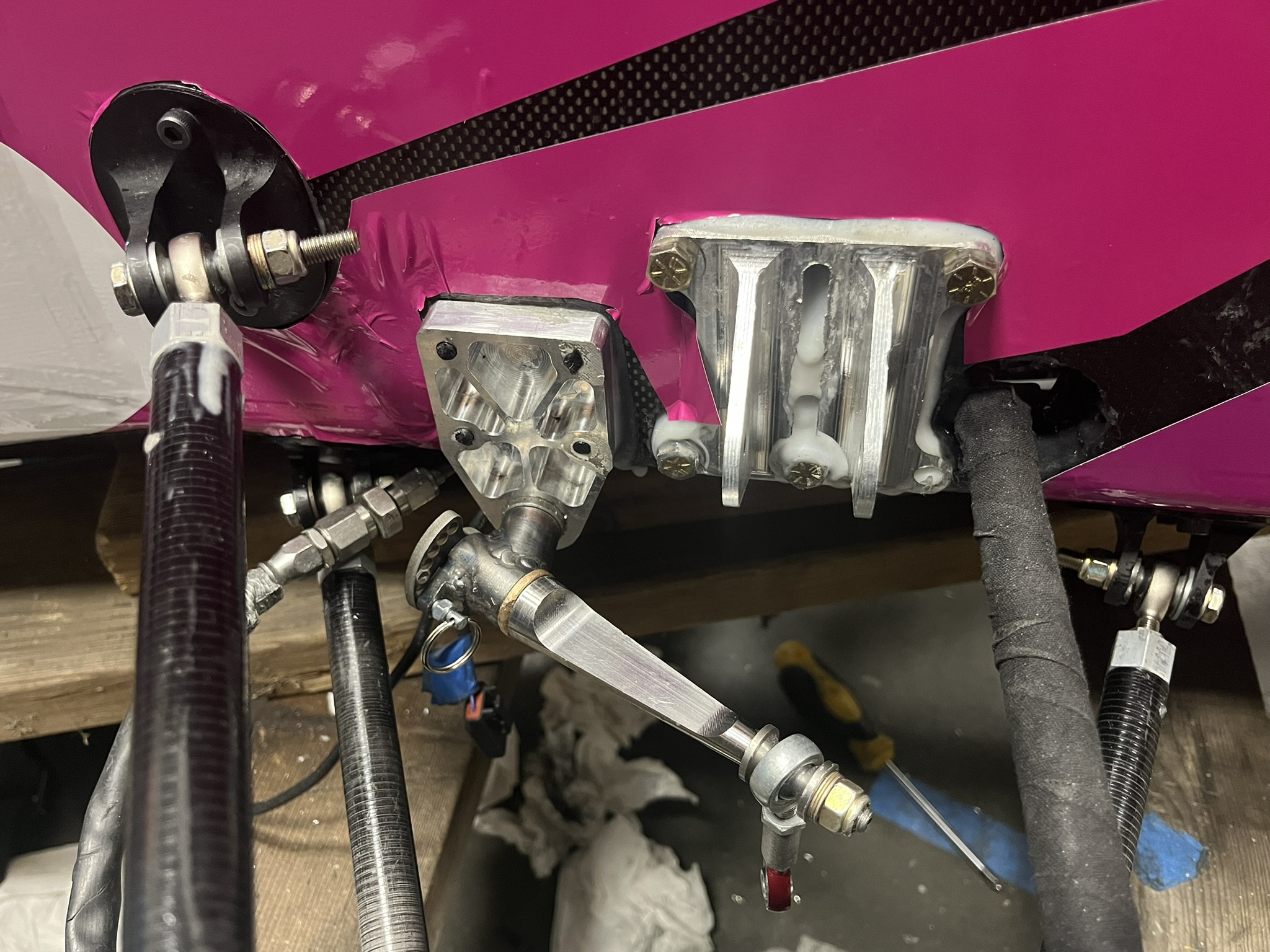

Assembly & indexing

- Integrated spring-loaded detents so blade angle (and thus stiffness) could be adjusted quickly

- Ensured the mechanism could be reached and adjusted easily with the bodywork on

Results & Takeaways

- Sub-30 second stiffness changes, compared to ~10–15 minutes with previous FARB designs

- A simulation-backed stiffness range, making setup decisions more quantitative and less guesswork

- Practical experience combining:

- Multibody simulation (Simulink) as a design tool

- 3D-printed soft jaws and waterjet jigs to do precise machining on irregular parts

- Reinforced how powerful it is to close the loop between simulation, fixturing, and on-car usability, especially for components that directly affect vehicle balance and driver confidence