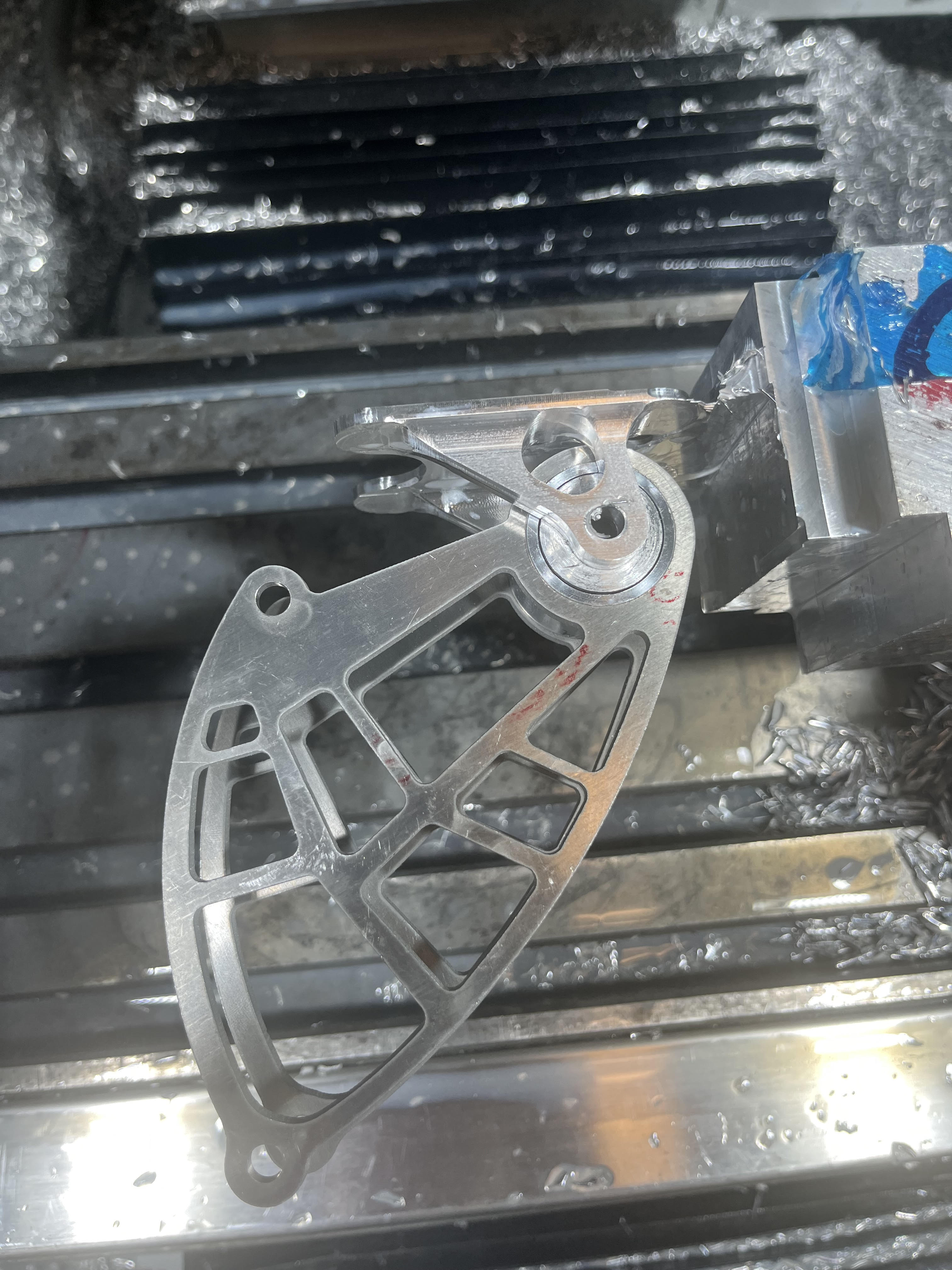

Topology Optimized Bellcranks

On my first season on the Formula UBC team, I redesigned our front bellcrank using parametric CAD, FEA, and topology optimization to cut mass while increasing stiffness and simplifying the assembly.

On our Formula UBC car, the front bellcrank links the pullrods to the dampers and sets the effective motion ratio of the front suspension. I redesigned it to be lighter, stiffer, and faster to manufacture.

Goals

- Cut mass to reduce unsprung weight and improve responsiveness

- Increase stiffness so the linkage behaves like an lever, not a spring

- Simplify manufacturing to save time and minimize points of failure

Design & Analysis

- Rebuilt the bellcrank as a parametric model in SolidWorks

- Ran FEA to study stress and deflection under peak suspension loads

- Used topology optimization to guide the final geometry

- Simplified the bearing stack to reduce part count and improve load paths

Outcome (vs previous design):

- ~20% mass reduction

- ~35% increase in stiffness (from deflection comparisons in FEA)

Manufacturing

- Bellcrank plates:

- 7075-T6 aluminum, waterjet cut and honed to press onto the bearing assembly

- Bearing assembly:

- Turned 6061 aluminum components plus bearing + retaining ring

- Chassis mount:

- Machined on a 4-axis CNC to maintain pivot alignment and match the complex carbon monocoque surface

Results & Takeaways

- Achieved a lighter, stiffer linkage with about 30% less production time

- Got end-to-end experience: CAD → FEA/optimization → machining → integration

- Learned how to balance optimization with manufacturability and assembly, and how small choices in the bearing stack and interfaces affect stiffness and reliability