Using Stages to Make More Stages at Zaber Technologies

Custom peristaltic pump system for automated cyanoacrylate dispensing with non-contact tube sensing, Python state machine control, and computer vision verification. Designed and built during a co-op at Zaber Technologies to improve consistency and speed in production assembly.

During my 4-month co-op at Zaber I owned an effort to automate cyanoacrylate dispensing on a magnet pick-and-place line. The project involved mechanism design, non-contact sensing, state-machine control, and a CV proof-of-concept for deposit verification.

System Overview

The complete system follows this flow:

- Pickup tube submerged in CA reservoir

- First sensor detects fluid level and bubbles before the pump (critical because air in the pump kills consistency)

- Peristaltic pump drives fluid through PTFE tubing

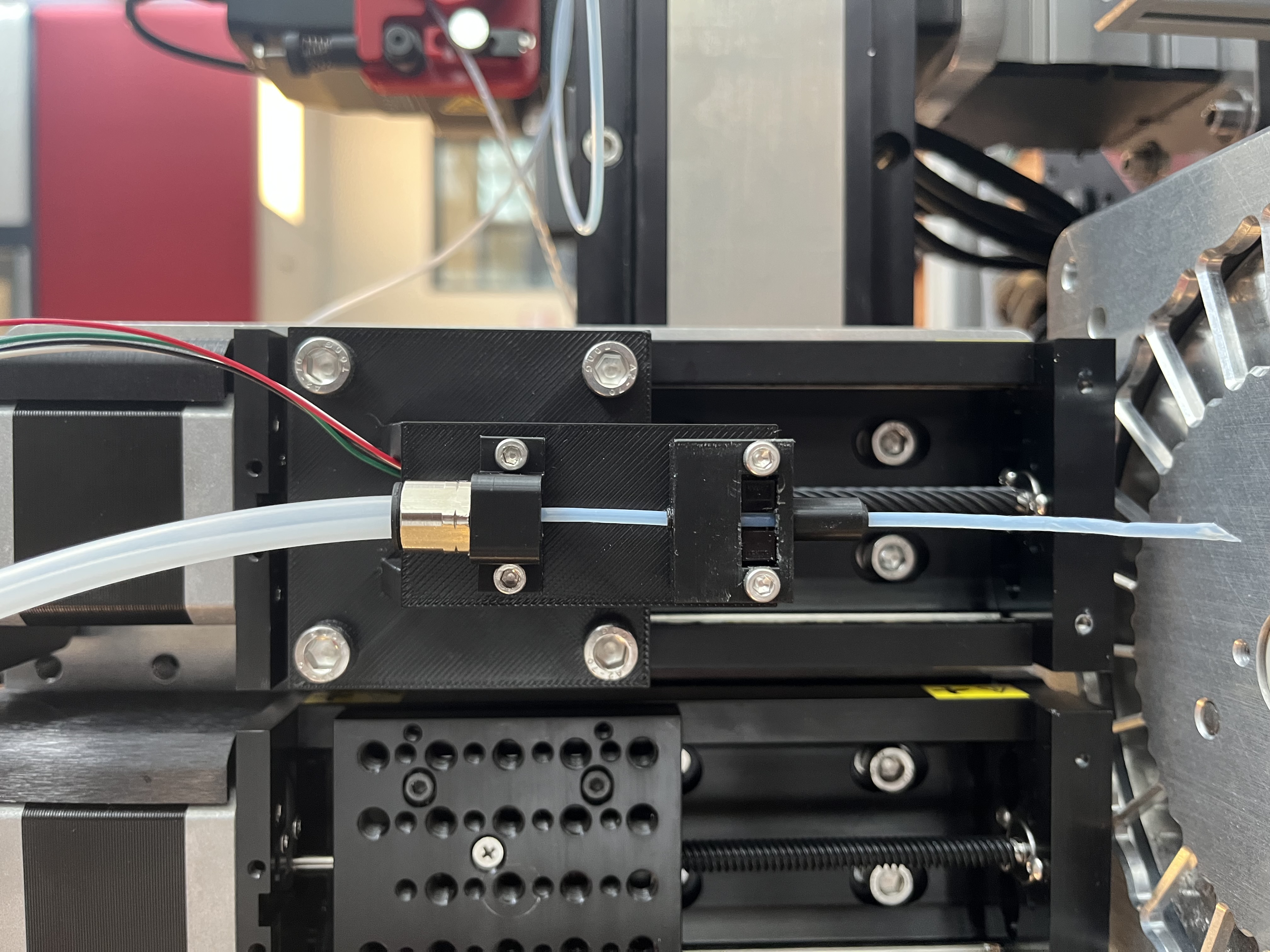

- Bowden tube routes fluid to the vertical stage

- Second sensor at the nozzle assembly with TPU split clamp

- PTFE syringe tip dispenses onto the part

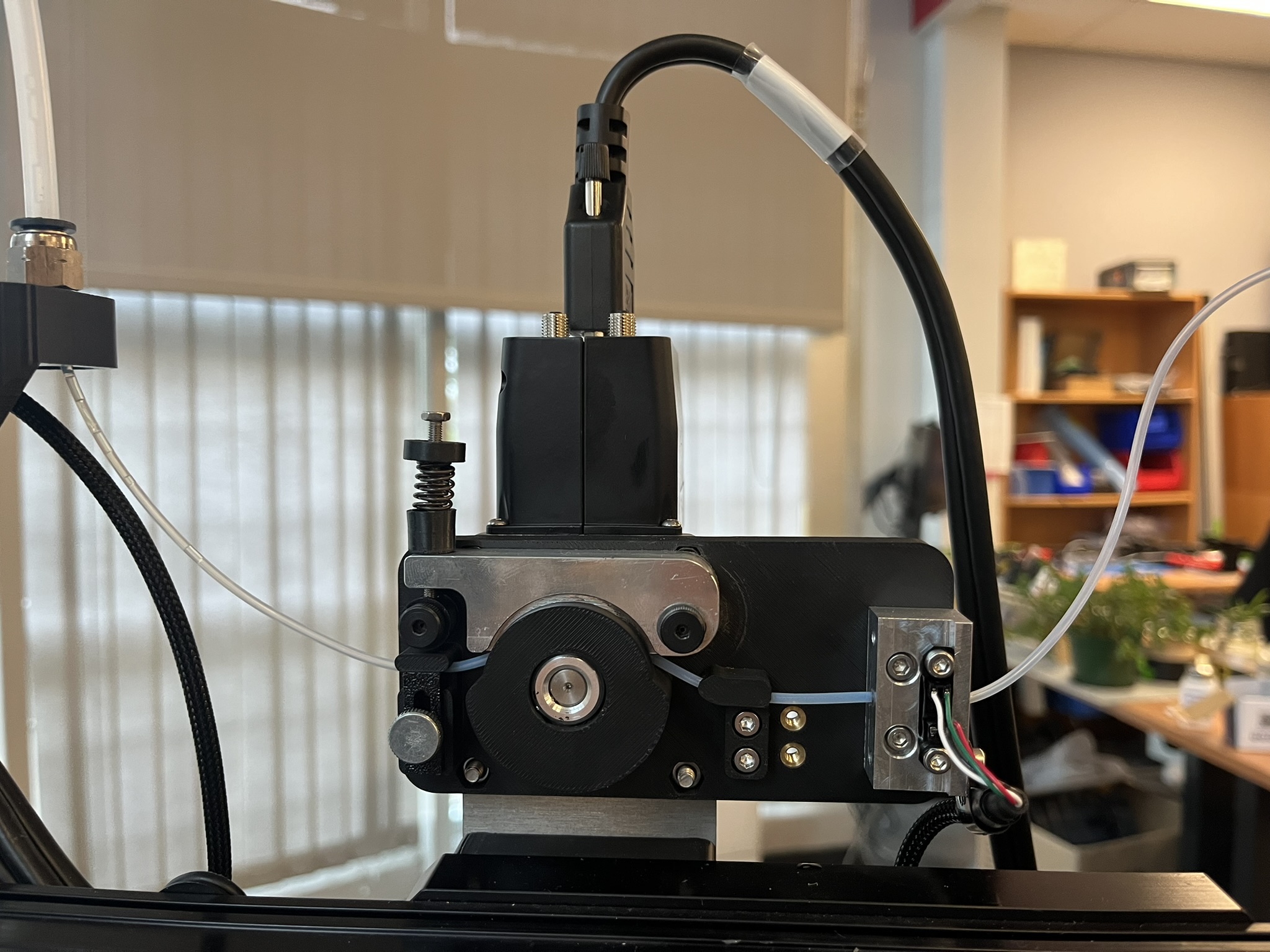

Left: Pump assembly showing inlet sensor, peristaltic pump housing, and tube routing. Right: Nozzle assembly mounted on Z-axis stage with outlet sensor and dispense tip

Cross-section showing outlet sensor, TPU split clamp, and PTFE syringe tip support

Things I Accomplished

- Designed a custom peristaltic pump and non-contact tube sensor that reliably primes, dispenses, and detects bubbles

- Wrote a Python state machine with prime/purge/bubble-detect routines and safety interlocks

- Switched production from 2-part epoxy to cyanoacrylate after testing—higher strength/heat resistance and no mixing

- Prototyped computer vision deposit verification of clear fluid on brushed steel with glare

Peristaltic Pump

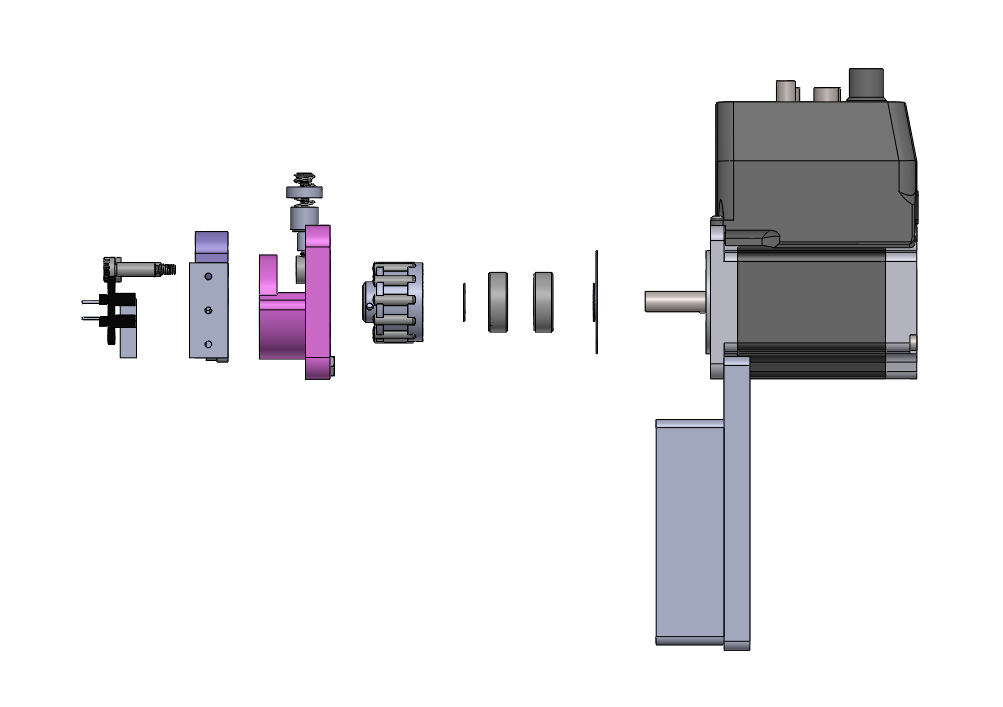

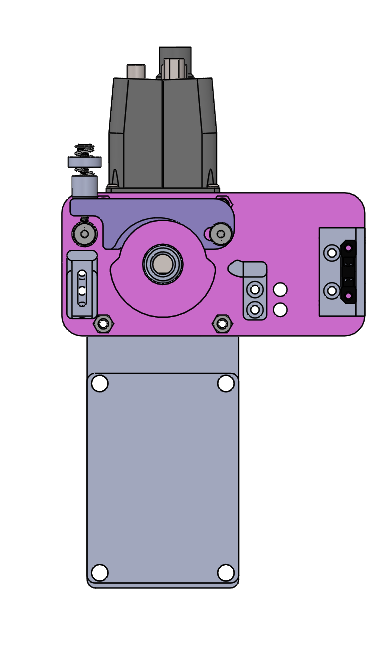

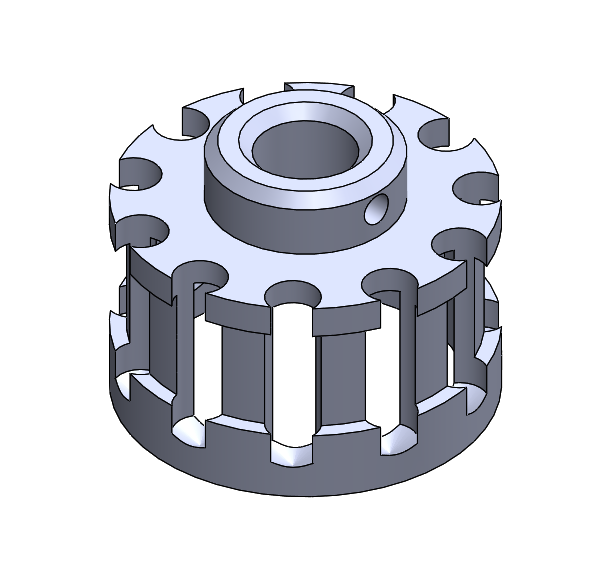

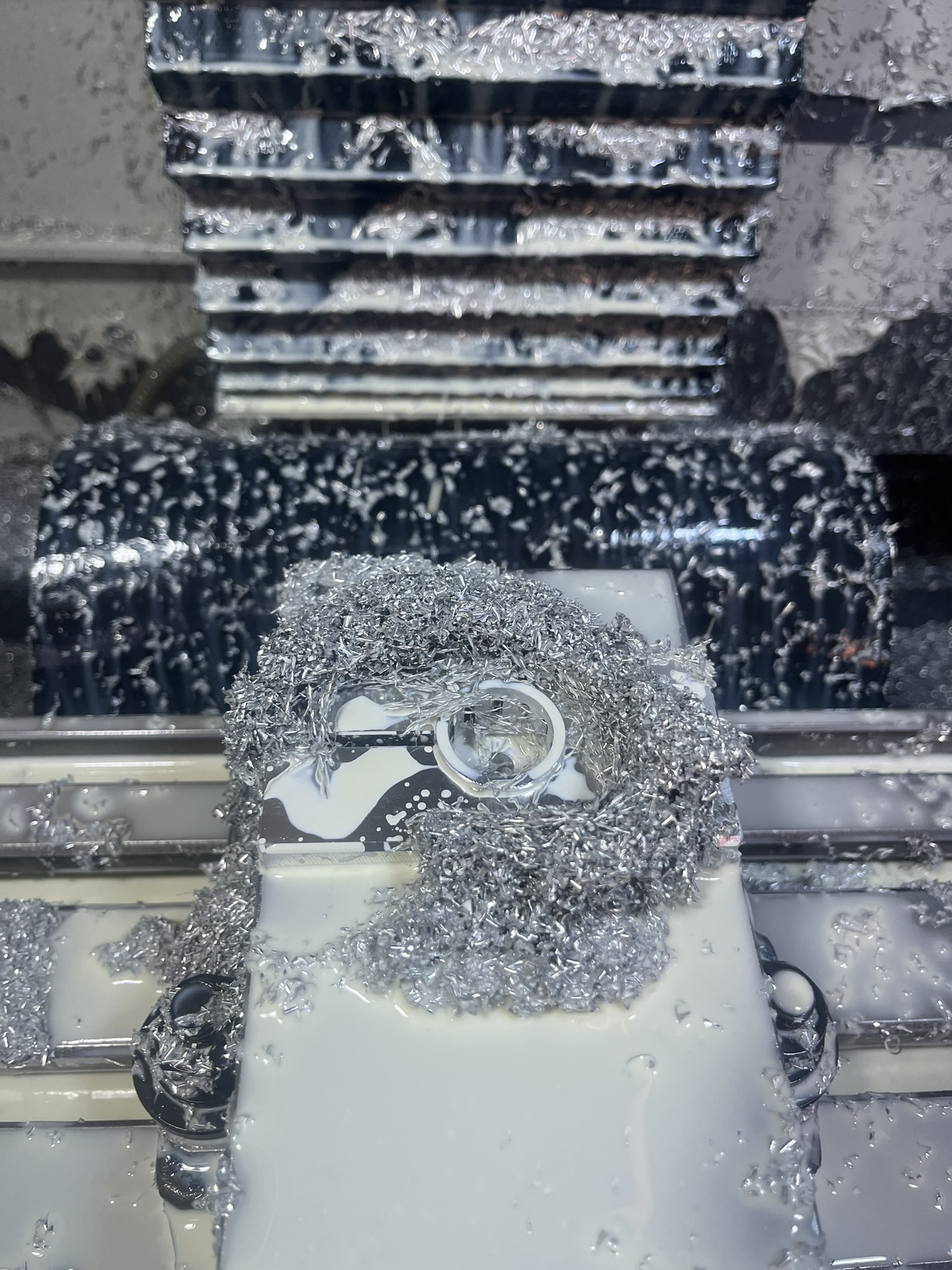

Early pumps struggled with tube life and inconsistent dispense volume because PTFE (needed for CA compatibility) doesn’t rebound like silicone; it pancakes under occlusion. After a lot of prototypes, the final design used many small metal dowel rollers spinning on stacked skateboard bearings: low friction, gentle on the tube, and fast.

Left to right: Exploded assembly view, front view showing roller arrangement, rotor detail

Left: Rotor being machined. Right: 3D-printed soft jaws holding the rotor for secondary operations

Non-Contact Tube Sensing (Prime, Flow, Bubbles)

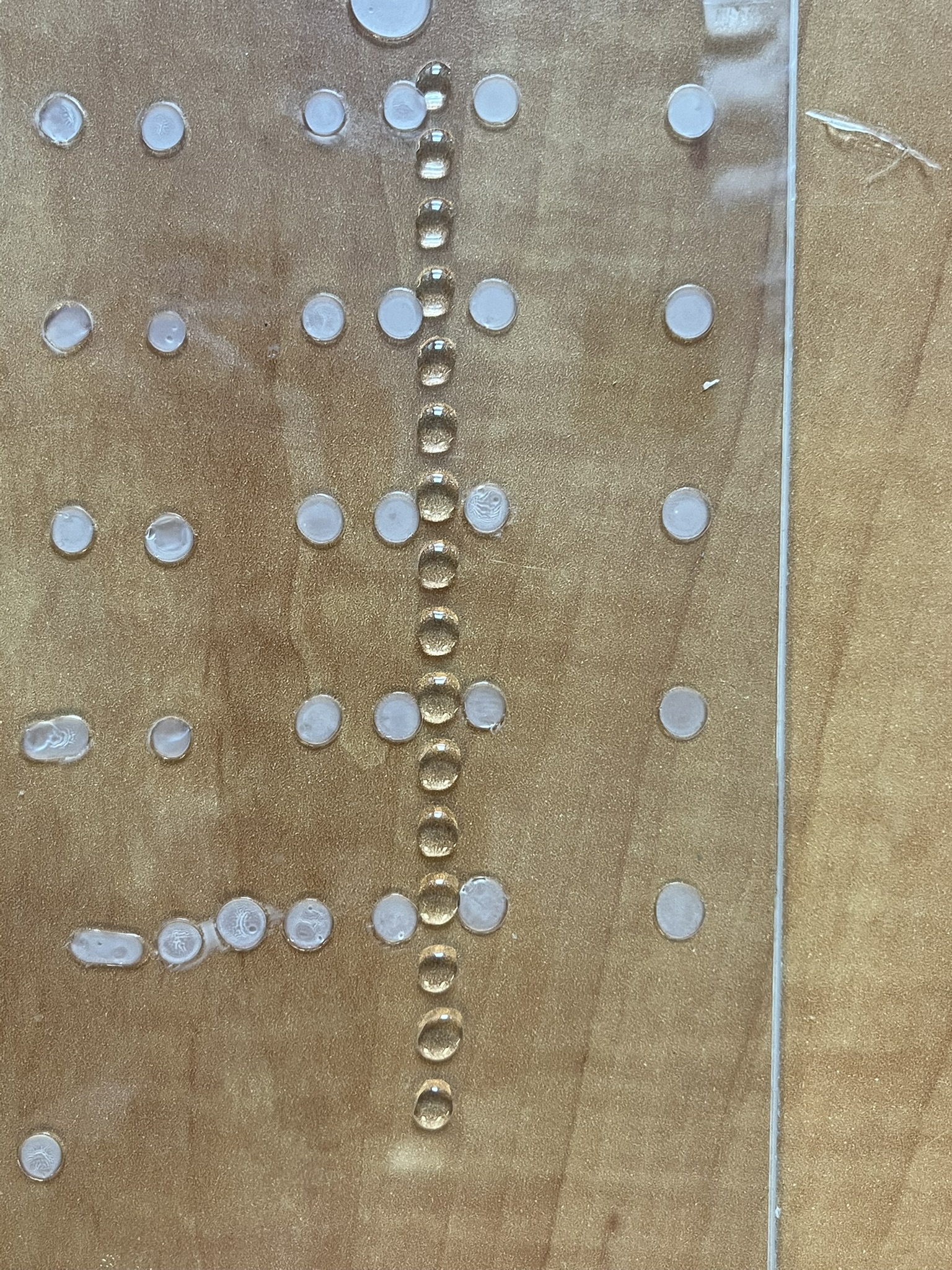

I wanted flow detection without touching the adhesive. The trick: a wide-aperture phototransistor/photointerrupter aimed through the PTFE tube. When the tube is filled with clear CA, refraction directs more light into the receiver than when it’s empty. The “filled” case produces a higher signal (the opposite of the usual opaque-fluid method). To do this I:

- Printed a micrometer-adjust test jig to sweep tube position and find the max-SNR spot

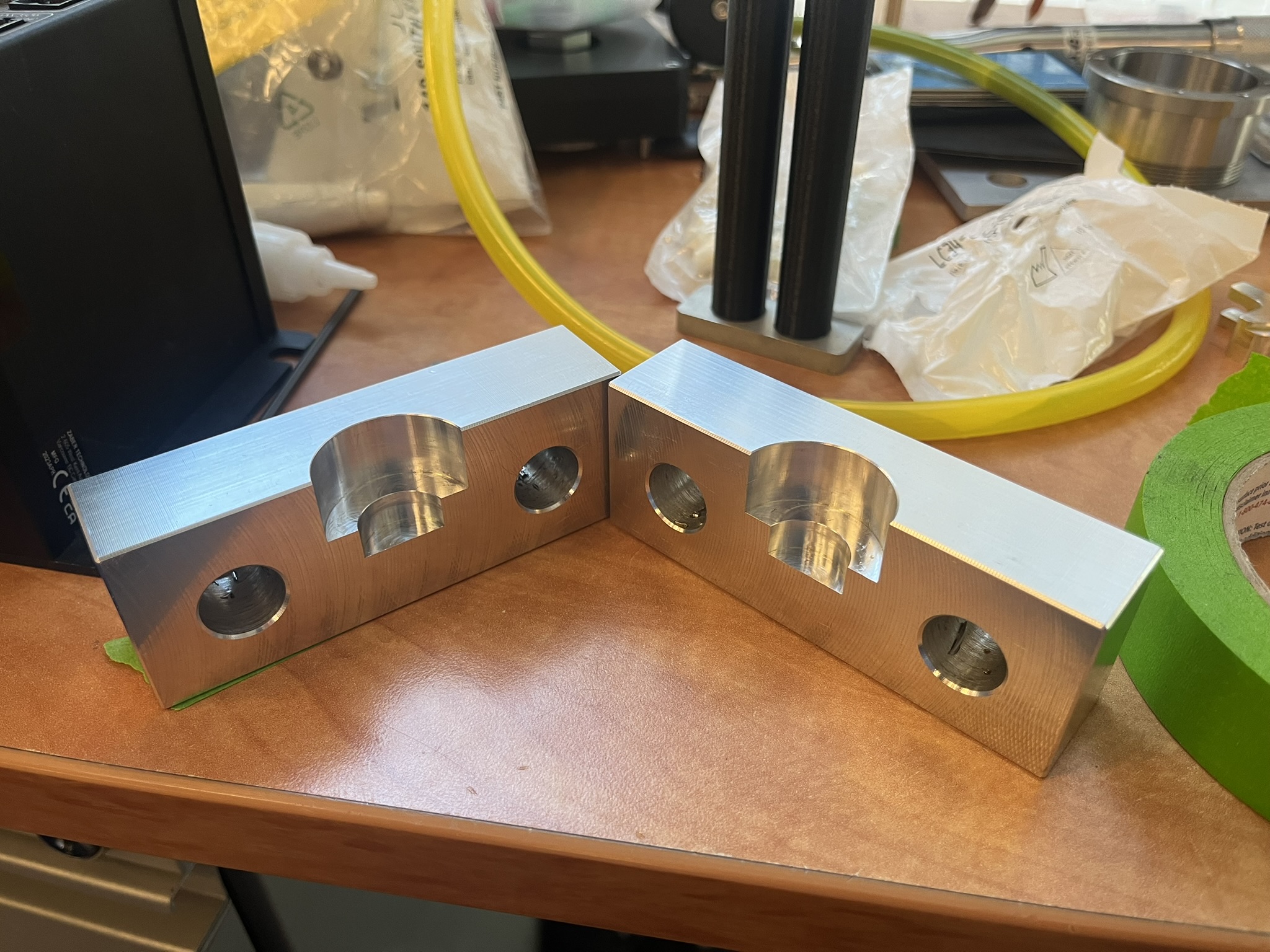

- Designed and machined a 6061 sensor housing so the tube seats repeatably at that sweet spot

- Logged signals during prime to auto-detect “no tube,” “empty,” “filled,” and bubble events

Early prototype of the sensor housing and optical detection system

Control: Python State Machine

All machine logic lived in a Python state machine:

- Prime: drive until sensor goes high, then short purge

- Purge: dispense until deadspace between sensor and nozzle opening is filled

- Bubble detect: watch for rapid signal oscillations and re-prime automatically

- Safety: lockouts for operator interaction, E-stop, and time-at-nozzle

This robust state machine is what allows for unsupervised operation.

Cyanoacrylate > Epoxy

I evaluated adhesives on lap/shear and peel fixtures (using yoke samples and jigs I designed), then moved production to cyanoacrylate (CA):

- No mixing, clean handling, high strength, and excellent heat resistance for our use-case

- CA requires PTFE tubing and careful pump design, but the automation benefits were worth it

Left: Shear/peel test fixture for bond strength validation. Right: Testing dispense consistency

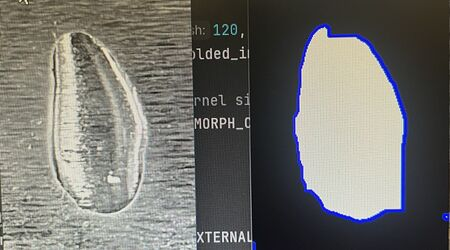

CV Proof-of-Concept:

Clear adhesive on brushed steel is near-worst-case: low contrast, specular hot spots. I built a PoC with controlled lighting and OpenCV morphology/contour logic that segmented deposits well enough for a go/no-go gate. With more time, I’d move to a shrouded camera with a ring light.

Impact

- The dispenser moved from prototype to production on new flagship products

- Prime/purge reliability and bubble detection reduced rework and operator time

- The CV PoC is queued to push toward lights-out dispense verification

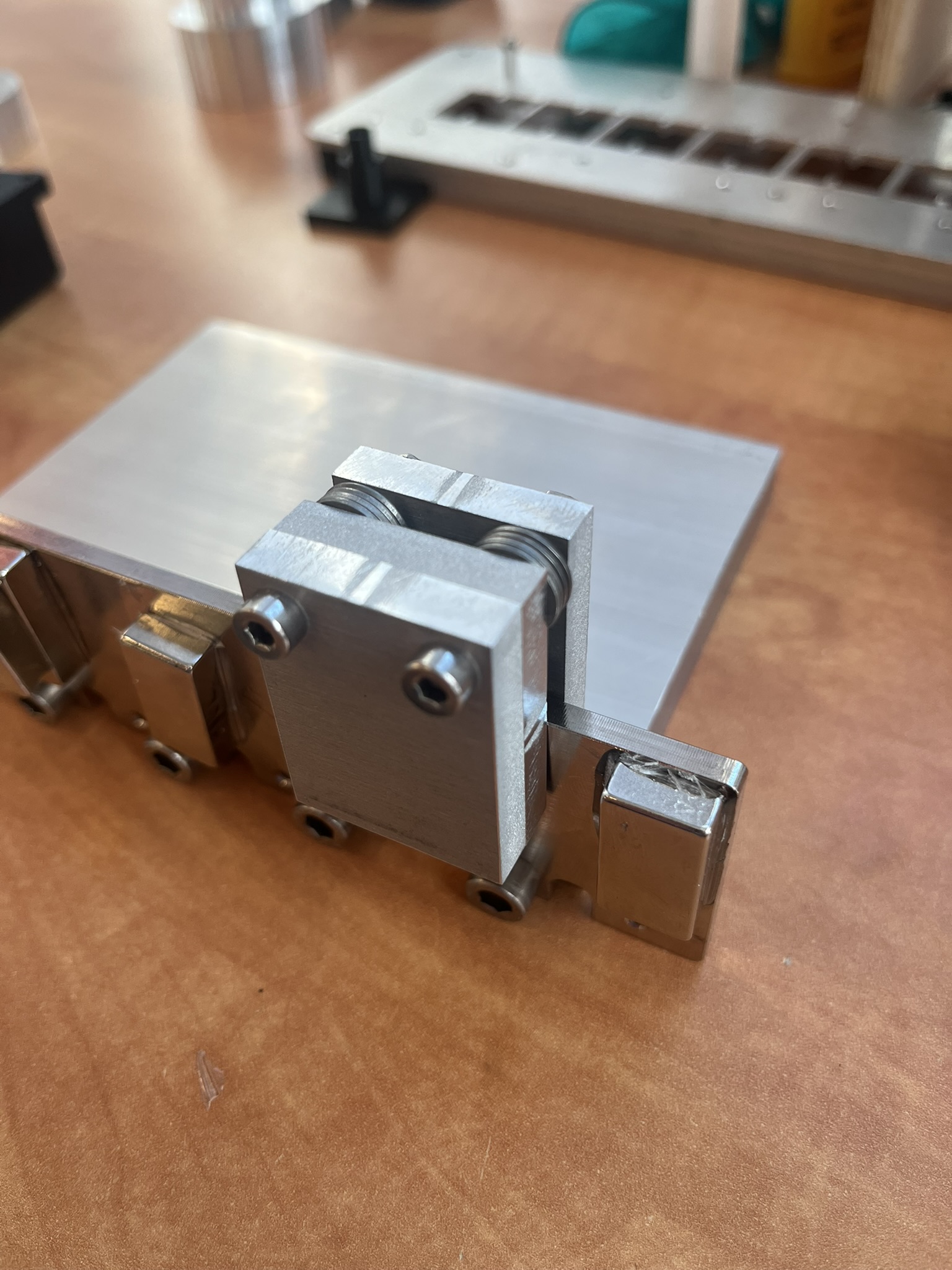

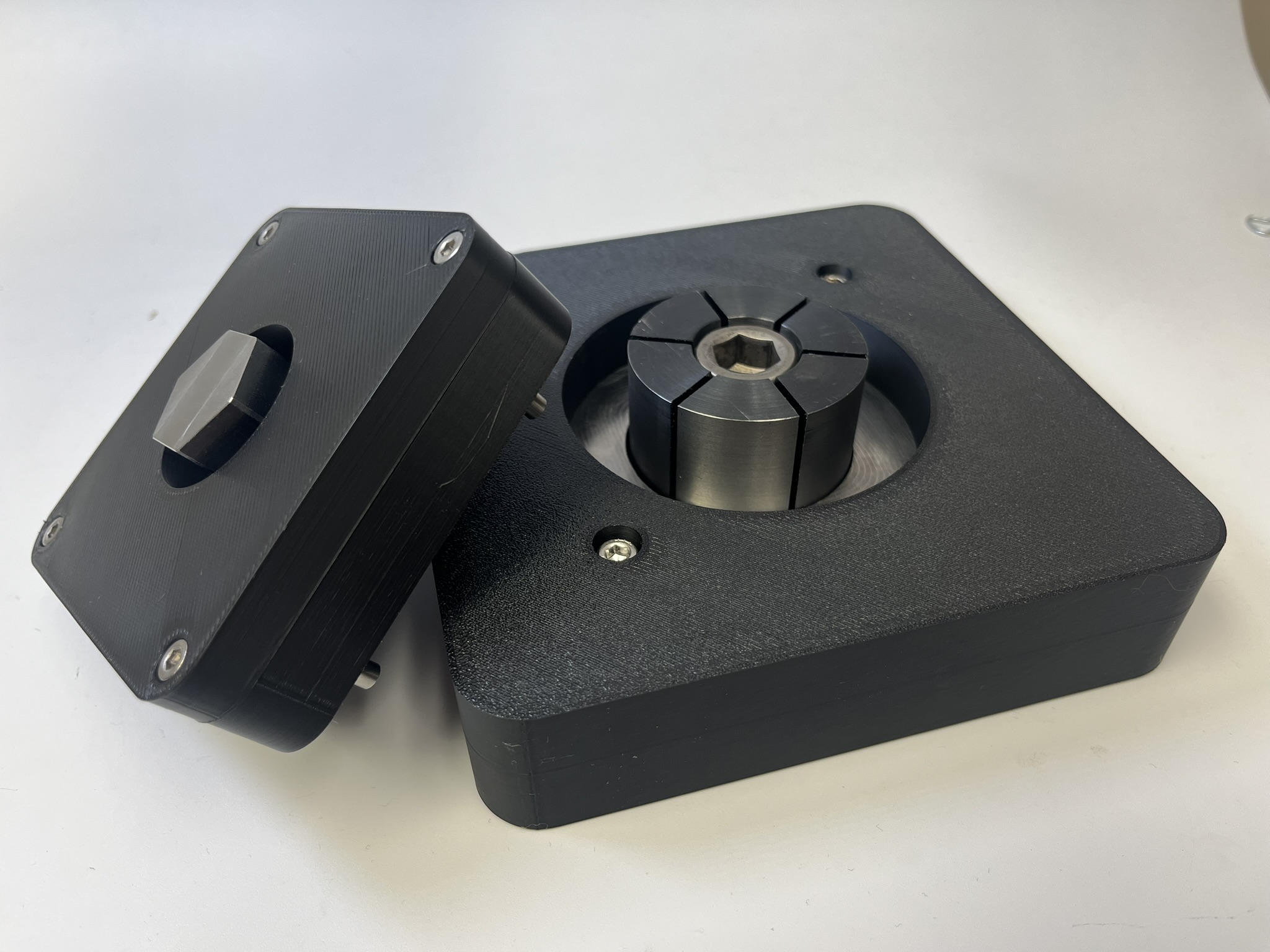

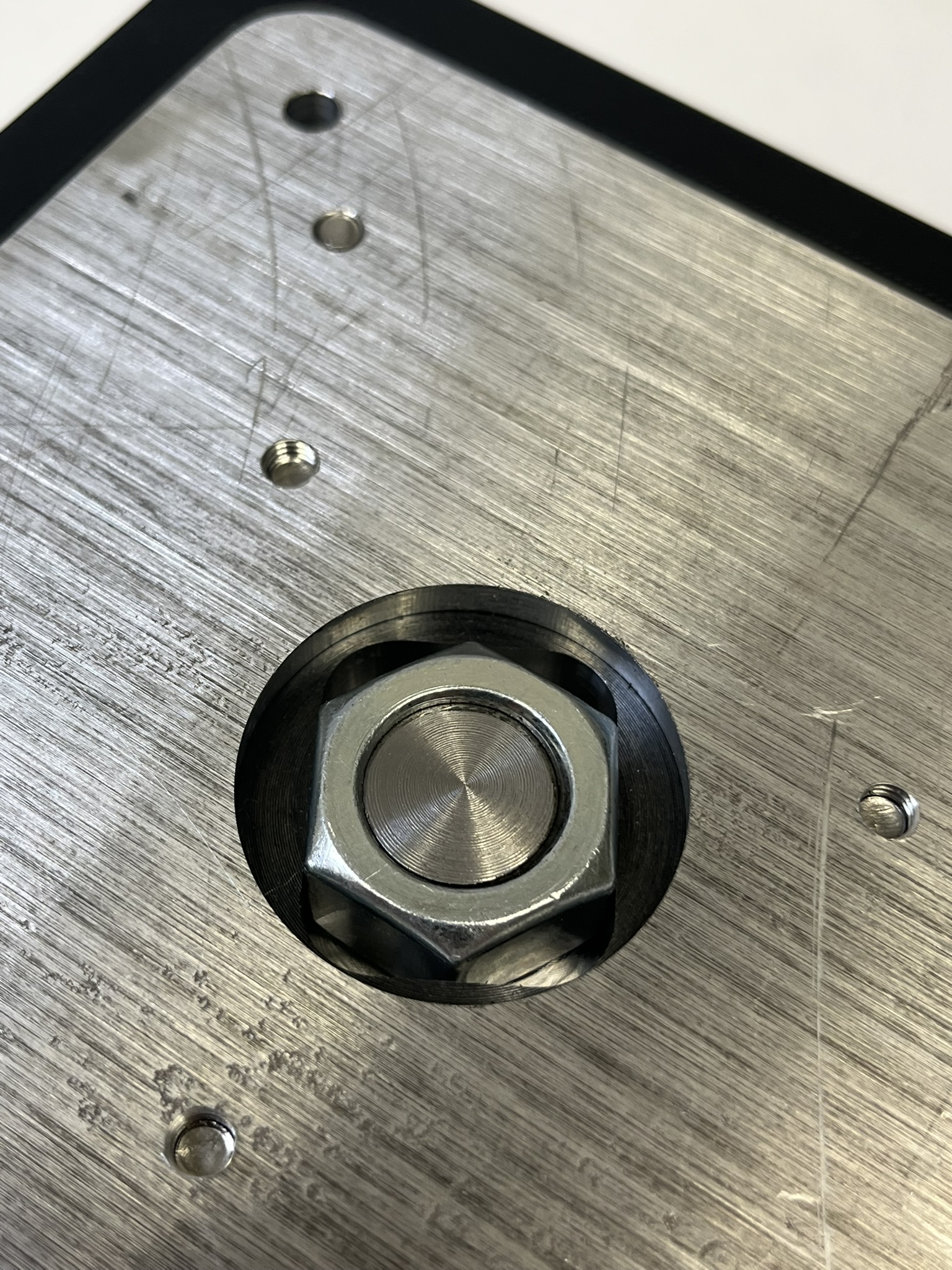

A Side Project: Pin-Wrench Bearing Preload Tool

I also designed a pin-wrench + ID expansion clamp for preloading bearings. It kept torque on-axis and made setup safer. The 3D-printed covers prevented the steel tool from attracting the large magnet assembly.

Left: Close-up of the steel fixture with machined key feature. Right: Recessed pocket machined into the ID expansion clamp for flat workbench mounting